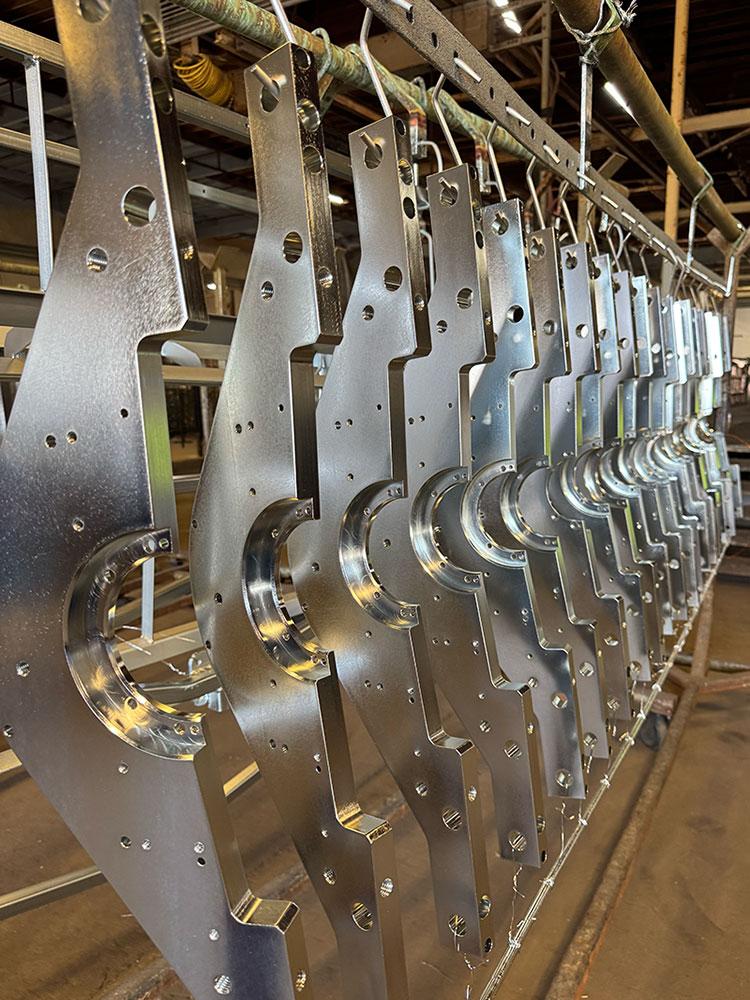

Metal Finishing Group offers a comprehensive range of metal finishing processes designed to meet rigorous standards, including Military Specifications (Mil Specs). With large tank capabilities (up to 12 ft long, 6 ft wide, and 6 ft deep), we can handle a wide variety of part sizes.

Finishing Processes

Mil Specs are available for all methods.

- Anodizing:

- Type II

- 10 Colors

- Type III (Hard)

- Type II

- Black Oxide Steel

- Black Oxide Stainless

- Cadmium Clear

- Cadmium Yellow

- Chemical Film, Clear or Yellow

- Chrome, Decorative Trivalent

- Copper

- Electropolish

- Gold

- Nickel, Bright

- Nickel, Electroless Mid Phos

- Nickel, Electroless High Phos

- Nickel, Sulfamate

- Passivate, Nitric or Citric 1, 2 & 3

- Phosphate, Manganese

- Phosphate, Zinc

- Silver

- Tin

- Zinc Black Type II – SC 1& 2

- Zinc Black Type II – SC 3

- Zinc Black Type II – SC 4

- Zinc Clear Type I & III – SC 1 & 2

- Zinc Clear Type I & III – SC 3

- Zinc Clear Type I & III – SC4

- Zinc Yellow Type II – SC 1 & 2

- Zinc Yellow Type II – SC3

- Zinc Yellow Type II – SC4

- Zinc Type IV

- Zinc Clear Type V – SC 1 & 2

- Zinc Clear Type V – SC 3

- Zinc Clear Type V – SC 4

- Stripping

- Bead Blast, Grain, Polish

- Masking & Plugging

- Expedite Available

- Baking per ASTM B 850-98 Post Bake @ 3740-4280 F per Customer Request:

- 4 Hours

- 6 Hours

- Rockwell Hardness HRc:

- 31-33 8 Hours

- 33-36 10 Hours

- 36-39 12 Hours

- 39-43 14 Hours

- 43-45 16 Hours

- 45-47 18 Hours

- 47-49 20 Hours

- 49-51 22 Hours

- 51+ 24 Hours

- Hydrogen Embrittlement Bake 3500 F

- 3 Hours

- Hardness Bake 4500 F

- 2 Hours

- Certification of Compliance – No Charge